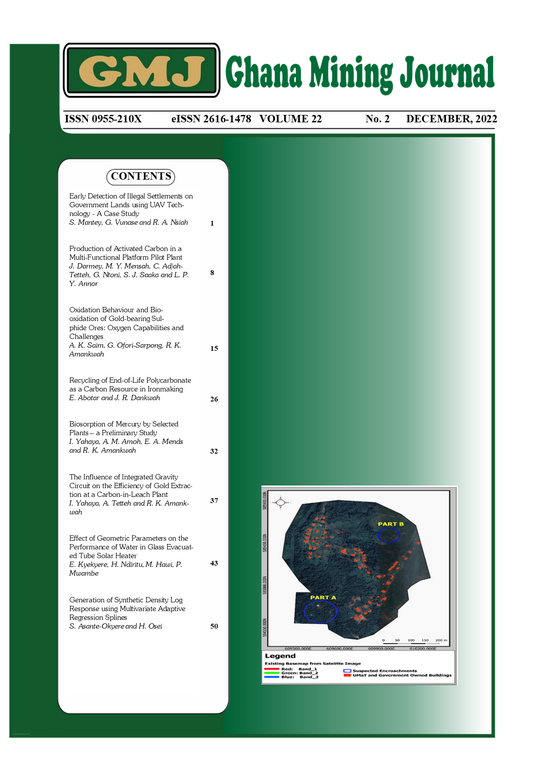

Recycling of End-of-Life Polycarbonate as a Carbon Resource in Ironmaking

Abstract

Globally, millions of end-of-life Polycarbonates (PC) are generated annually. Landfill disposal is one of the primary options for handling end-of-life PCs. There is a possible potential release of Bisphenol-A (BPA) from PC via hydrolysis or leaching when disposed at landfill sites. In this work the use of end-of-life PC as reductant for the production of metallic iron from Mbalam iron oxide was investigated in a horizontal tube furnace through the composite pellet approach. Elemental analysis of the charred PC shows a carbon content of (78.92 wt %) and hydrogen content of (7.07 wt %) which are reasonably above those of various forms of coals and can be recovered for use as reductant in metal extraction processes. Composite pellets of high-grade Mbalam iron ore (assaying ~97 % Fe2O3) with charred end-of-life PC were heated from room temperature to 800 °C and then between 800-1300 °C in a continuous stream of pure argon and the off gas was analysed continuously using an infrared (IR) gas analyser. Elemental analyses of samples of the reduced metal were performed chemically for its oxygen content using a LECO oxygen/nitrogen analyser. Gas emission studies revealed the emission of large volumes of the reductant gas CO along with CO2. It is further demonstrated that end-of-life PC is effective in reducing iron oxide to produce metallic iron with reduction in oxygen content from 30.99 wt % to 0.0372 wt % corresponding to 99.88 % in less than 2400 s.

Downloads

Published

Issue

Section

License

Copyright (c) 2022 Emmanuel Abotar, James Ransford Dankwah

This work is licensed under a Creative Commons Attribution 4.0 International License.

Copyright © 2021 University of Mines and Technology (UMaT), Tarkwa. Ghana