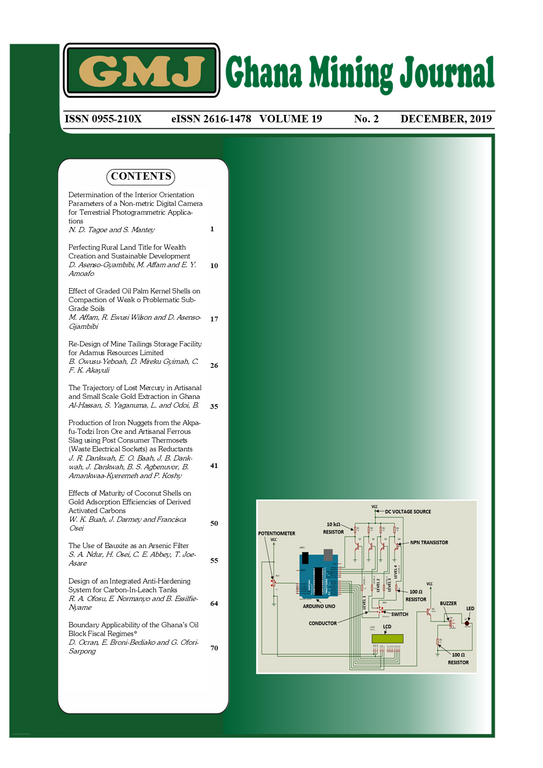

Design of an Integrated Anti-Hardening System for Carbon-In-Leach Tanks

Abstract

Slurry density monitoring is of paramount importance in the industrial world. Most industries, especially cement and mineral processing industries, employ this method to obtain good quality products. However, most Carbon-In-Leach (CIL) tanks of gold processing industries do not use slurry density monitoring systems. As a result, many a time agitation difficulties occur when the slurry begins to harden. This paper therefore seeks to design an integrated anti-hardening system for Carbon-In-Leach tanks, with the aid of a microcontroller, to monitor the density of the slurry in order to prevent it from hardening. Slurry density measurement was achieved with the help of a strain gauge pressure sensor and a couple of level sensors. Atmega 328p microcontroller board was programmed to continuously compute the density of the slurry from values of pressure and level of slurry in the tank indicated by the pressure and level sensors, respectively. The microcontroller responds to slurry hardening by activating a light emitting diode and triggering the piezo buzzer when a set point is reached. The designed circuit was successfully simulated using Proteus 8.2 design suite software to ascertain its functionality. Based on the results obtained, the light emitting diode and piezo buzzer activated when the set point was reached. It was concluded that the anti-hardening system is effective for constantly monitoring the density of the slurry to prevent it from hardening. It was also recommended that the mining industries could employ the designed system to monitor the density in order to prevent hardening of slurry in CIL tanks.

Downloads

Published

Issue

Section

License

Copyright © 2021 University of Mines and Technology (UMaT), Tarkwa. Ghana